Quality Control

Proudly Offering Complete Solutions for Anchoring Applications with the Highest Quality

Many chemical anchor manufacturers outsource the production of reacted resin and empty cartridges for their adhesive products. At Good Use Hardware Co., Ltd., we take pride in reacting the resin and producing the cartridges in-house, allowing us to maintain control over quality from raw materials to finished chemical anchors. We educate our employees with a "Quality First" philosophy and conduct strict quality checks at every stage of production. Good Use Hardware is certified by the ISO 9001 Quality Management System, ensuring that all our products meet the highest standards.

Resin: The Key Component in Chemical Anchor Production

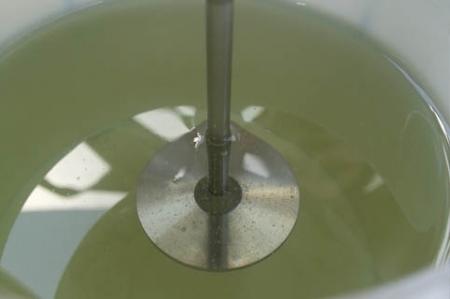

Quality control begins at the initial stage, allowing us to expand our product range. Our R&D team conducts extensive testing in our laboratory before initiating the resin reaction to ensure optimal quality. Since resin is the critical factor in chemical anchors, we exclusively use new materials for resin reactions to guarantee both quality and process stability.

Cartridge: The Ideal Packaging for Chemical Anchors

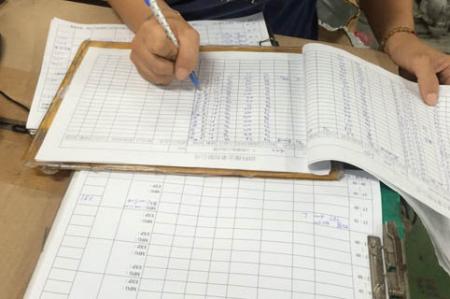

Having our own cartridge injection factory allows us to maintain consistent quality. Proper packaging is essential for chemical anchors, and we utilize only new, first-class plastic materials. Our quality control team meticulously records testing results for raw materials, semi-finished products, and finished products, adhering to our principle of 100% inspection for quality assurance. Furthermore, we offer a variety of cartridge volumes, including customized injection cartridges to meet specific customer needs.

Chemical Anchor - Excellent Bonding Strength Construction Adhesive

Ensuring the safety and longevity of a building is paramount; therefore, we prioritize quality at every stage, from materials to finished products. We conduct inspections and record results throughout the production process. Before shipment, we perform consistency testing through random inspections to verify performance. We also retain samples from every production batch after shipment, allowing us to track data when necessary. We are committed to providing high-quality chemical anchors that contribute to a safer and better world.