Engineering rebar connections chemical resin

GU-500 400ml Epoxy Chemical Anchor

Anchor bolt epoxy for construction engineering

2 part epoxy chemical anchor adhesive is wide using range in engineering as powerful adhesion and steady characteristic. High strength epoxy mortar is engineering quality and superior features. We accept small orders and self-use building project purchasing. Buying directly from factory is flexible, easy and quality secured. Epoxy concrete anchor is very potential product and affordable investment that is simple to start your own business.

Epoxy anchoring adhesive for engineering construction

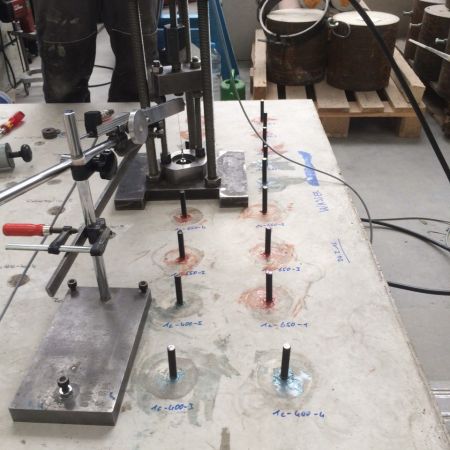

Epoxy chemical anchor are mostly used for engineering because the advanced tensile strength. Our epoxy bonding strength testing is performed by IWB Lab, Germany according to ETA 330499-00-0601 which is comprehensive European rule for rebar and threaded rods. Performance is approved of rebaring for structure extension, anchoring for structure reinforcement and studding for structure connections. Epoxy adhesive can use under wide-ranging installation temperature for all types of weather.

- Epoxy rebaring for structure extension

- Epoxy for anchor bolts in concrete

- Epoxy resin anchor bolts pull out testing

- Concrete anchor epoxy tensile strength test

What is the tensile strength of epoxy anchors?

The strength of rebar, concrete and epoxy glue are the key 3 factor of tensile strength. If one of them is low strength, the result strength is limited. For example, when rebar grade is low which may cause rebar break that can't reach maximum bonding strength. If concrete psi level is not strong enough that will lead to concrete broken. So when you know what fixing strength is required, should consider these 3 materials matching well. Below chart is reference adhesive strength by diverse rebar size under specific hole diameter and hole depth.

| Pressure | Destroy Haul Strength (Kgf/KN) | Safety Haul Strength (Kgf/KN) | Working Standard (mm) | ||||||

| Concrete Strength | 4,000 psi | 280 kg/cm2 | 4,000 psi | 280 kg/cm2 | Hole Diameter | Hole Depth | |||

| Rebar No. | #3 | (Φ10) | 3,607 | 36.4 | 1,202 | 12.1 | 13 | 90 | |

| #4 | (Φ12) | 6,409 | 64.7 | 2,136 | 21.6 | 16 | 125 | ||

| #5 | (Φ16) | 9,695 | 97.9 | 3,232 | 32.6 | 20 | 145 | ||

| #6 | (Φ20) | 13,655 | 137.9 | 4,552 | 46.0 | 25 | 170 | ||

| #7 | (Φ22) | 18,672 | 188.6 | 6,224 | 62.9 | 28 | 200 | ||

| #8 | (Φ25) | 24,032 | 242.7 | 8,011 | 80.9 | 32 | 225 | ||

| #9 | (Φ28) | 27,364 | 276.4 | 9,121 | 92.1 | 37 | 260 | ||

| #10 | (Φ32) | 31,730 | 320.5 | 10,577 | 106.8 | 40 | 290 | ||

| #11 | (Φ36) | 35,843 | 362.1 | 11,948 | 120.7 | 42 | 320 | ||

| Remarks: | 1. Concrete Strength fc': 280kg/cm2 (4,000 psi) 2. Rebar Strength: #3~#5 fy: 2,800 kgf/cm2, #6~#11 fy= 4,200 kgf/cm2 | ||||||||

Quality Certified Chemical Fixing In Germany

With more than 25 years experience and reputation, our chemical anchor also tested in many lab of different country per market demands. Quality approval of SGS, Germany IWB lab, Thailand AIT lab as well as environmental friendly certificate of VOC and LEED. Our factory is licensed factory of chemical anchor with government acknowledged. It's important to use the product make by legal factory and with quality certificate. Because every small fixing turn into stronger building and it's concerning personal safety.

- Low VOC chemical anchors

- Low VOC content according to LEED regulation

- Thailand bonding strength test by AIT lab

- Taiwan bonding strength test by SGS lab

- European bonding strength test by ETAG qualified lab

How to buy for small order or self-use project?

Click the links below to know more about Good Use hardware's online order, or send us an email and our sales team will provide you suitable item and estimated shipping cost. There are ways of payment and delivery that you can choose according to your demands.

- Related Products

650ml epoxy anchoring adhesive for high temperature installation

GU-500 650ml 1:1

1:1 ratio 650ml epoxy base injection mortar for anchoring projects in high temperature country.Two...

DetailsAdvanced epoxy chemical anchor for varying weather application

GU-500SD 400ml 3:1

Epoxy 400ml is strongest chemical anchor in our product range. Remarkable performance at high...

DetailsAdvance high strength epoxy chemical anchor for concrete mounting system

GU-500SD 400ml/585ml 3:1

High strength epoxy anchoring for aluminum solar panel concrete mounting system. Top-quality...

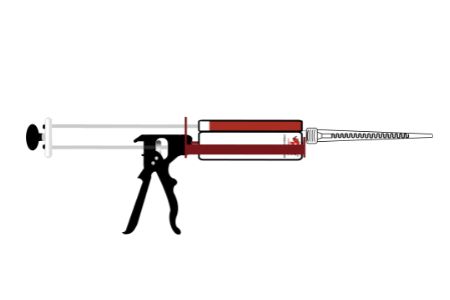

Details400ml dual component manual caulking gun

#810

#810 caulking gun is a price option for two component epoxy 400ml cartridge with mixing ration...

Details400ml dual component manual caulking gun

G34-400LA

G34-400LA dispenser is heavy-duty and efficient dispensing for 3:1 400ml epoxy adhesive. High...

DetailsMixing nozzle for 1:1 and 3:1 chemical anchor

#818

Static mixer nozzles are applied to adhesive cartridges to mix and dispense two component adhesives....

Details- Files Download

Pure Epoxy Catalogue

Bonding strength table on dry concrete by different hole sizes and depth. Especially for big diameter rebars/threaded rods.

DownloadGU-500 400ml Pure Epoxy Technical Data Sheet

Technical information of anchor design, curing time, edge distance, consumption per hole and installation procedure for GU-500 pure epoxy.

DownloadGU-500 SGS Tensile Strength Testing Report

Pire epoxy pull out strength report for various bolt sizes on 4000psi concrete according to ASTM E488-96 by SGS lab.

DownloadGU-500 AIT Tensile Strength Diameter of 25mm

Pure epoxy tensile test report of rebar fixing for 25mm hole size by Thailand AIT engineering lab. According to local market demands, our products will...

DownloadGU-500 AIT Tensile Strength Diameter of 16mm

Pure epoxy tensile test report of rebar fixing for 16mm hole size by Thailand AIT engineering lab. According to local market demands, our products will...

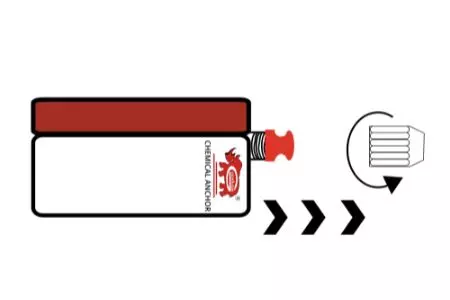

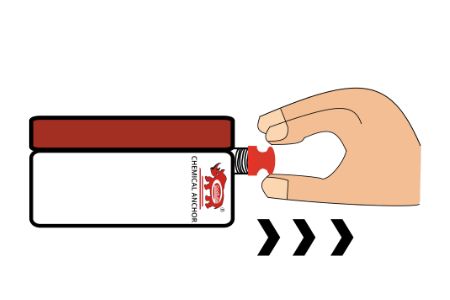

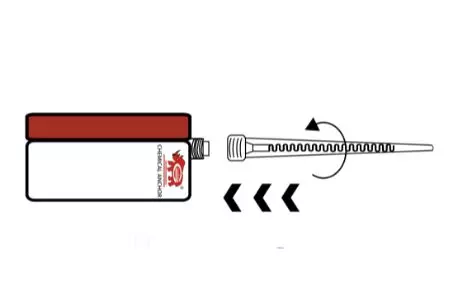

Download- Installation Guide

- Gallery

Engineering rebar connections chemical resin - Anchor bolt epoxy for construction engineering | Sold in 40 Countries Injectable Chemical Anchors Manufacturer Since 1997 | Good Use

Located in Taiwan since 1997, Good Use Hardware Co., Ltd. has been an injectable adhesive mortars and anchors manufacturer. Their main products, including Engineering rebar connections chemical resin, injection cartridges, chemical mortars, chemical anchors, anchor capsules, polyester resins and vinylester resins, which are sold in 40 countries.

Reputable factory of chemical anchor in Taiwan produces the widest range of adhesive anchor solutions for your concrete anchoring applications. with more than 15 years manufacturing experience for Chemical Anchor System, Injection Cartridge System, Construction Chemical Mortar and more. Certified chemical anchor solutions with wide selections of adhesive materials including epoxy anchors, concrete anchors, resin anchors for heavy loads in rebar application, diamond drilled holes and anchoring in solid concrete. Non-drip formula, ideal for overhead installation. Chemical anchor bolt and anchor fixings included for efficient, hassle-free, labor-saving chemical anchoring.

Good Use has been offering customers certified and tested high-quality chemical anchors, both with advanced technology and 25 years of experience, Good Use ensures each customer's demands are met.